Food & Beverage

EQUIPMENTS & SERVICES WE OFFER

Food & Beverage

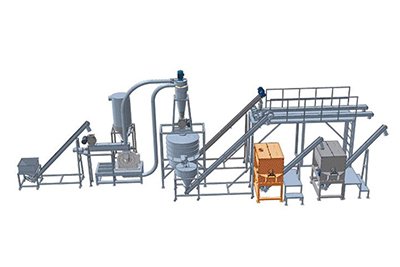

Food & Beverage Turnkey Processing Solutions

Food preparing and drink fabricating are perplexing cycles with much basic Screening and Filtration Applications.

With rich mechanical ability, we are cooking the prerequisites of different Food Processing Industries by giving them our best administrations to finish turnkey arrangement. Our total turnkey answer for different food handling businesses incorporates planning, designing, assembling, execution and appointing.

Food Processing

Makers of food, soy-based, oils and meat items rely on ABISL preparing innovations to remain on the beat of their business sectors. Whatever the food application, our food handling hardware, modules and complete preparing lines empower the stockpile of items to buyers at serious costs – while keeping up the most elevated levels of cleanliness and wanted taste characteristics.

A. We Provide Equipment's with Material Handling

- Pneumatic Transfer system

- Positive displacement transfer system

- Bulk Transfer system

B. Processing Equipment's

- Complete Processing Plant

- Grinders

- Mixers

- Blenders

- Conveyors

- Sieving systems

- IBC

- Hoppers

- Agitator tanks

- Self Cleaning Filters

- Silos

C. Product Packing

- Horizontal packing (Automatic/Semi-Automatic)

- Vertical Packing (Automatic/Semi-Automatic)

- Carton Eractor

On the pulse of innovative solutions and the food production industry

Accomplishing the ideal taste, stable time span of usability and faultless cleanliness levels requires tight control of cycle timing and temperatures, just as cautious and right crude fixings and materials.

Achievement begins with seeing how to take advantage of every fixing and crude material – from dry powders to tacky sugars, gooey fluids to shear or warmth delicate fixings, for example, flavor enhancers and embodiments. Exact taking care of, dosing and blending of fixings at that point keep creation costs low by limiting spillage and waste.

ABISL solutions guarantee sterile creation just as productive, viable cleaning set up (CIP) of gear and handling lines – agreeing in full with the most rigid administrative norms for clean applications.

Equally importantly, ABISL enables you to:

- Increase production yields and maintain long running times, through high availability and uptime levels

- Decrease ingredient and product loss levels by getting more out of your raw materials

- Reduce your consumption of utilities, such as energy and water, and recycle waste streams. For instance, our SELF CLEANING FILTERS can help create a zero-litre water discharge site.

Beverage Processing

The overall hunger for business refreshments keeps on developing – soda pops, juices, packaged waters, espresso, tea, brew, juice, wines, and so on Fruitful refreshment creation requires capitalizing on crude materials and keeping up wanted finished result qualities through safe, financially savvy and reasonable multi-stage handling. ABISL supplies gear, modules and complete preparing lines arranged to meet the particular necessities of individual drink makers and breweries.

On the pulse of beverage production and innovation

Drink preparing organizations and distilleries face various difficulties. The expenses of crude materials, fixings and creation are for the most part expanding, yet you actually need to convey delicious, low-valued beverages to perpetually requesting customers.

You should likewise agree with progressively rigid limitations set on your items, and limit the ecological effects of your creation set-up.

ABISL drink gear and preparing arrangements assist you with beating these difficulties by lessening creation expenses and cutting utilization of energy, water and different utilities, just as guaranteeing excellent cleanliness levels.

Our hardware and arrangements guarantee solid, sterile creation just as proficient, compelling cleaning set up (CIP) of creation lines – going along in full with the strictest administrative guidelines for clean applications.

Similarly significantly, ABISL enables you to:

- Increase production yields and maintain long running times, through high availability and uptime levels

- Decrease ingredient and product loss levels by getting more out of your raw materials

- Reduce consumption of utilities, such as energy and water, and recycle waste streams.

For instance, our latest range of separators cuts energy consumption by 30%.

Why choose ABISL?

- Increase uptime and production yields

- Ease commissioning, qualification and validation

- Easy cleaning and maintenance

- Comply with all relevant standards

- Provide in-batch and batch-to-batch consistency by safeguarding product characteristics and quality

- Combine maximum hygiene with maximum efficiency

- Reduce waste handling and consumption of utilities like water and energy